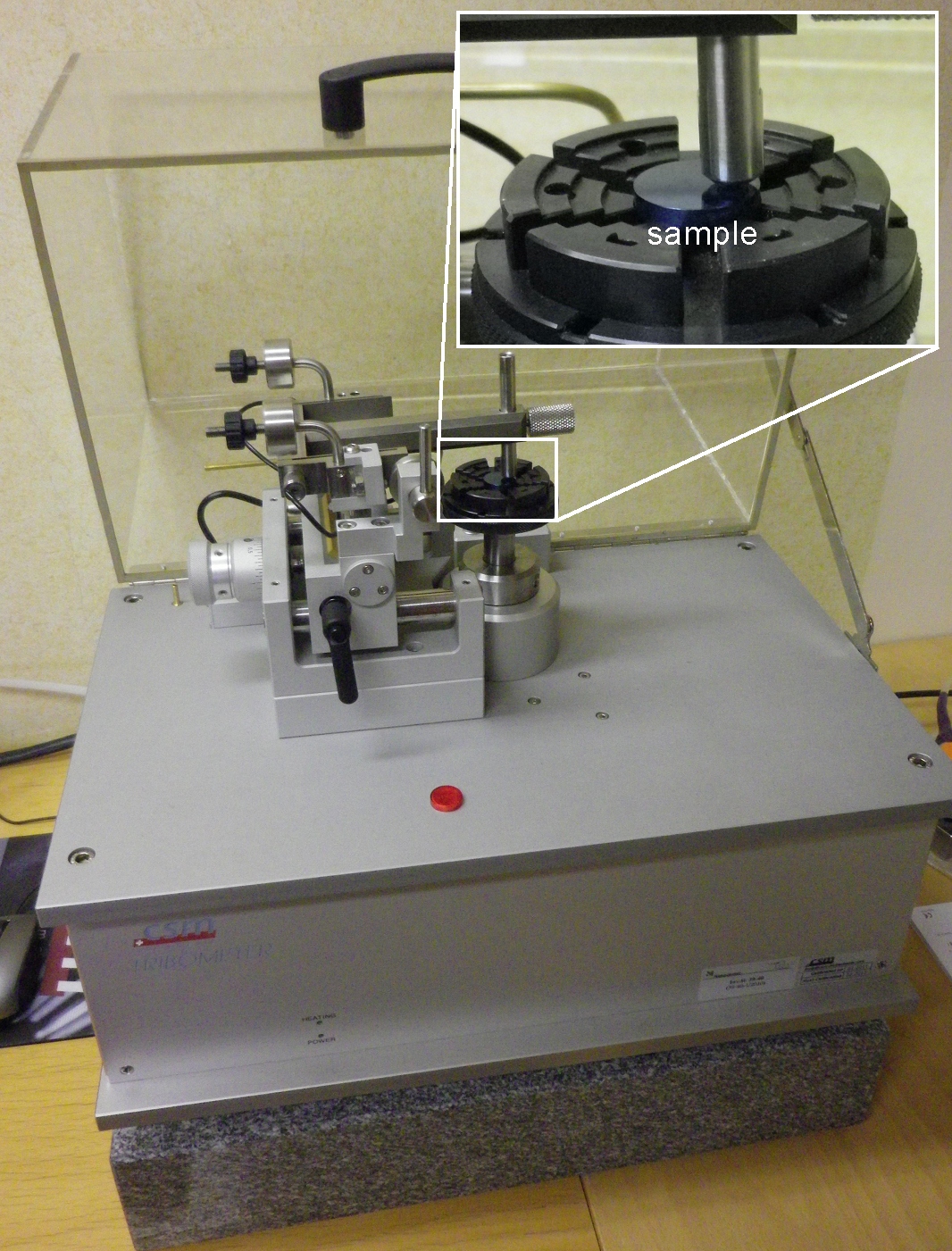

Tribometer 220V 50/60Hz

Manufacturer: CSM Instruments

Year: 2011

Financed from EU (ESRD) founds from the operation Center of Excellence in Nanoscience and Nanotechnology – CENN Nanocenter 2010 – 2013.

The tribometer is used for characterization of friction and wear. In its basic configuration it performs the standard pin-on-disk test where the disk is the sample and the pin is a standard ball. During the test the friction coefficient is measured as a function of time. After the test is completed the wear track cross-section on the sample is measured by a profilometer (not part of this equipment). Using these data the wear rate is calculated. Advanced analysis of the wear pattern by other techniques is possible as well (optical microscopy, SEM, EDS, etc). The tribometer configuration is essential for evaluation of tribological properties of hard coatings, especially the ones with low wear rate, such as nanostructured hard coatings.

Sample geometry:

- Flat round samples (diameter 10–50 mm, thickness 0.5–10 mm)

- Counterbody: 6 mm ball (steel, Al2O3)

- Motion type: rotary, oscillating

- Load range: 1–30 N

- Operating temperature: ambient–150 °C

- Operating media: dry, liquid

Responsible person: asst. prof. Miha Čekada, +386 (0)1 477 3796, miha.cekada@ijs.si,

Equipment location: Department of Thin Films and Surfaces (room 128), Jožef Stefan Institute, Jamova 39, 1000 Ljubljana

Requested level of experience: completition of a training

Reservation: to be discussed with responsible person