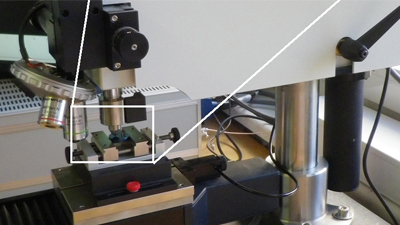

Revetest Scratch tester

Manufacturer: CSM Instruments

Year: 2011

Financed from EU (ESRD) founds from the operation Center of Excellence in Nanoscience and Nanotechnology – CENN Nanocenter 2010 – 2013.

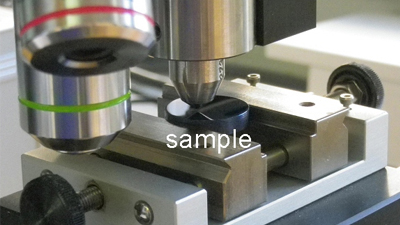

The scratch tester is used for characterization of adhesion of thin films. It uses a diamond tip which is drawn along the sample surface by pressing a predefined load (or load ramp). Several parameters are recorded in-situ: scratching force, scratching coeffictient, penetration depth and acoustic emission. After the scratching procedure a post-treatment evaluation includes: residual depth, acquisition of the optical image of the whole scratch and visual determination of critical loads. The equipment configuration is particulary useful for analysis of nanolayer and nanostructured hard coatings.

Sample geometry:

- Flat samples (lateral size 5–30 mm, thickness 0.5–10 mm), cylindrical samples (diameter 5–15 mm)

- Stylus: Rockwell C diamond (200 µm diameter)

- Loading type: constant, ramp, incremental

- Load range: 0–200 N

- Loading rate: 0–500 N/min

- Scratching force: 0–200 N

- Microscope objectives: 5×, 20×

Responsible person: asst. prof. Miha Čekada, +386 1 477 3796, miha.cekada@ijs.si

Equipment Location: Department of Thin Films and Surfaces (room 128), Jožef Stefan Institute, Jamova 39, 1000 Ljubljana

Requested level of experience: completition of a training

Equipment reservation: to be discussed with responsible person