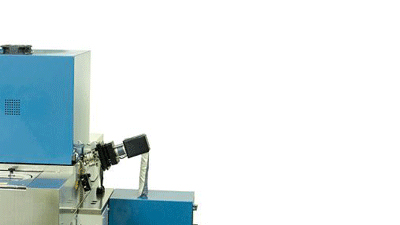

ALD System TFS 200

Manufacturer: Beneq Oy

Year: 2013

Atomic deposition system is intended for the application of different atomic layers. Since one of the goals in CENN Nanocenter is to test number of new nanomaterials and their potential use in industry, the Atomic deposition system will accelerate significantly the final prototyping. At the same time it will allow the functionalization of nanomaterials and thin nanostructured layers and similar systems constructed in advance with other methods. Such systems are extremely interesting as they allow easy production of sub-nanometer components, which have recently been the subject of great interest both in research as well as in industrial circles. Atomic deposition system is in use for a long time, today is also used in developing and manufacturing advanced nano-electronics on silicon base.

Atomic layer deposition (ALD) is a thin film growth method based on sequential introduction of precursors and nitrogen purges into the reactor. Each precursor adsorbs to the exposed surface area and there reacts with the other precursor(s), while excess precursors and unwanted chemical products are flushed out of the reactor with high purity nitrogen purging pulses. The number of cycles determines the final film thickness.

Currently, we have three precursors installed: hafnium precursor (TEMAH), aluminum precursor (TMA), and oxygen precursor (H2O). Our system is used for growing HfO2 and Al2O3 thin films, which can be used as gate dielectrics, anti-corrosion layers, etc.

Responsible person: Peter Rodič, peter.rodic@ijs.si

Equipment location: Laboratory K3, IJS, Jamova 39, 1000 Ljubljana

Requested level of experience: to be discussed with responsible person

Equipment reservation: to be discussed with responsible person