The company wanted to check the lighting parameters.

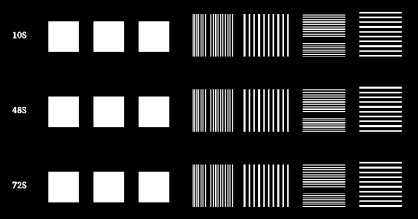

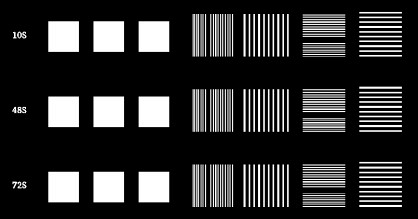

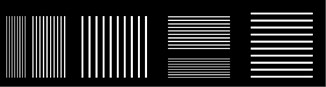

As part of this project, we approached consulting the company by illuminating thin slices with a light-sensitive polymer photo frameable material. The lighting was done in the shape of a pyramid, with patterns of horizontal and vertical lines. Differences between slice patterns in terms of width, depth, and a number of field contacts.

The consultation also included the analysis of samples with a focused ion beam scanning electron microscope with the cross-sectional analysis technique, which determined the shape, width, and depth of the field contacts. Multi-step patterns have been shown to have longer and shallower field contact, and less-step samples have deeper and narrower field contact. Optimal patterns have been shown to be those with shallower and narrower field contacts. At the end of the consultation, we identified the focus of further development with the company.

The consulting service project was implemented through the NANO-REGION project (Interreg IT-SLO)